- -65%

Cooking Appliances

add remove

Cooking Appliances

add remove

Pizza & Grill

add remove

Pizza & Grill

add remove

Refrigeration

add remove

Refrigeration

add remove  Combi Steamer

add remove

Combi Steamer

add remove

Kitchen Appliances

add remove

Kitchen Appliances

add remove

Rinsing & Cleaning

add remove

Rinsing & Cleaning

add remove

Retail Refrigeration

add remove

Retail Refrigeration

add remove

Cafe & Ice Cream

add remove

Cafe & Ice Cream

add remove

Airstream Trailer

add remove

Airstream Trailer

add remove

(200 x 136 px) (5).png) Smart-Gastro

add remove

Smart-Gastro

add remove

Cooking Appliances

add remove

Cooking Appliances

add remove

Pizza & Grill

add remove

Pizza & Grill

add remove

Refrigeration

add remove

Refrigeration

add remove  Combi Steamer

add remove

Combi Steamer

add remove

Kitchen Appliances

add remove

Kitchen Appliances

add remove

Rinsing & Cleaning

add remove

Rinsing & Cleaning

add remove

Retail Refrigeration

add remove

Retail Refrigeration

add remove

Cafe & Ice Cream

add remove

Cafe & Ice Cream

add remove

Airstream Trailer

add remove

Airstream Trailer

add remove

(200 x 136 px) (5).png) Smart-Gastro

add remove

Smart-Gastro

add remove

Product benefits

Design

quality

Connection

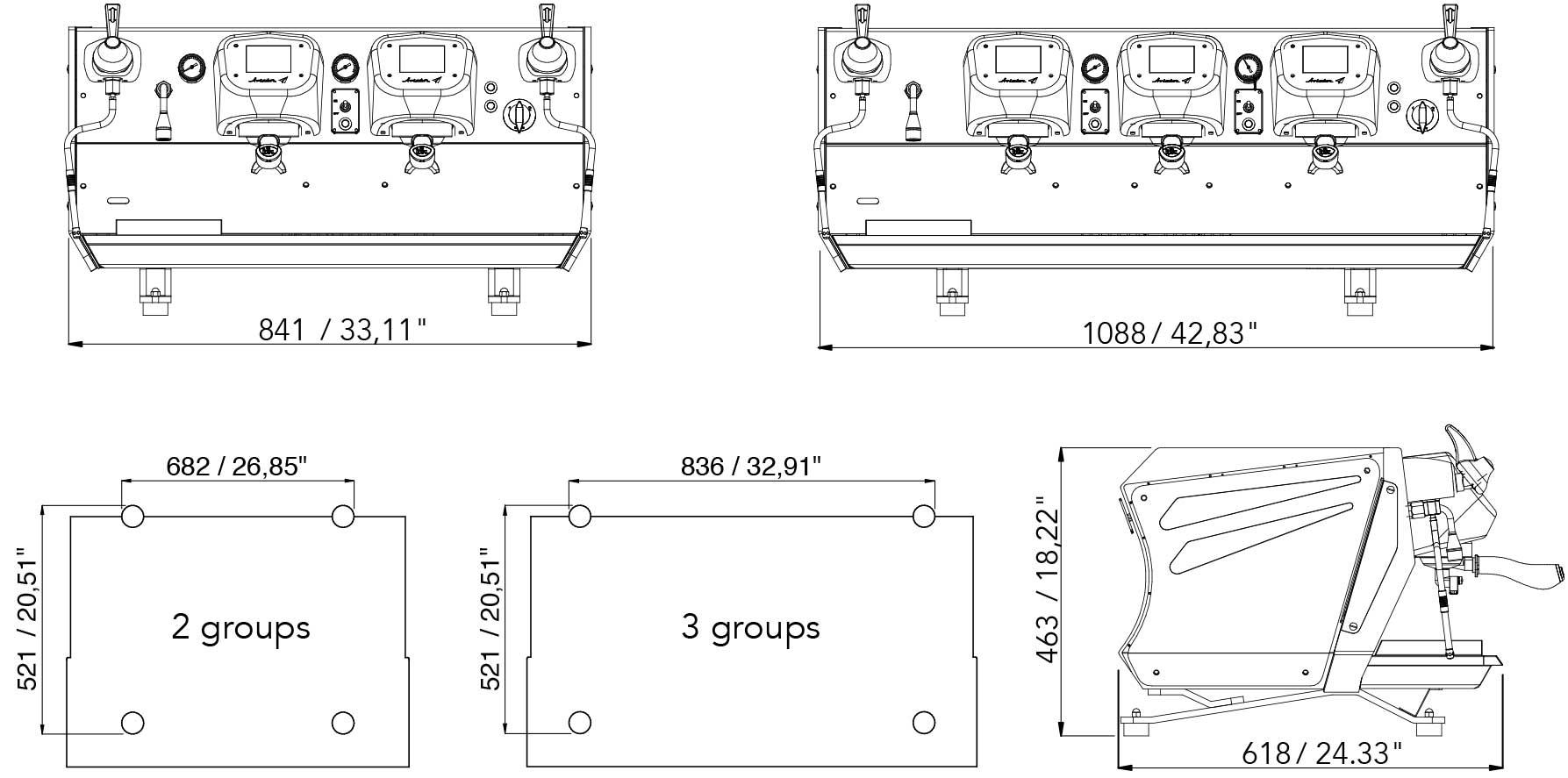

Dimensions

Scope of delivery

Instructions

Guidelines

steel

steel White

White Black

Black

Data sheet